Mesa Vista Water Storage Tank Project

WATER STORAGE TANKS

The AVHCWD system has four existing bolted steel potable water storage tanks. AVHCWD has a combined storage capacity of 260,000 gallons. The storage tanks pressurize AVHCWD’s distribution system pressure zones while the system’s wells are off. The tanks are located on two separate properties owned by the BLM. The Mesa Vista Tank Site is located at the southern terminus of Mesa Vista Street and has an approximate elevation of 3,440 feet above mean sea level. The Mesa Vista Tank Site has three storage tanks that each have a maximum storage capacity of 20,000 gallons and serve AVHCWD’s Lower Zone. The system’s wells supply water directly to the distribution system, with excess capacity filling the Mesa Vista tanks. When water demands exceed the supply from the wells, the tank level drops. The Central Tank Site is located at the southern terminus of Central Road and has an approximate elevation of 3,645 feet above mean sea level. The Central Tank Site has one bolted steel storage tank that has a maximum capacity of 200,000. An abandoned tank is also located at the site. The Central Tank serves AVHCWD’s Upper Zone. The Central Tank delivers water from the Lower Zone via the Roundup Booster Station. The Lower Zone pumps water to the Upper Zone, with excess supply filling the Central Tank. The Central Tank can deliver water through the Upper Zone back to the Lower Zone through a combination pressure-reducing/pressure-sustaining valve located at the Roundup Booster Station.

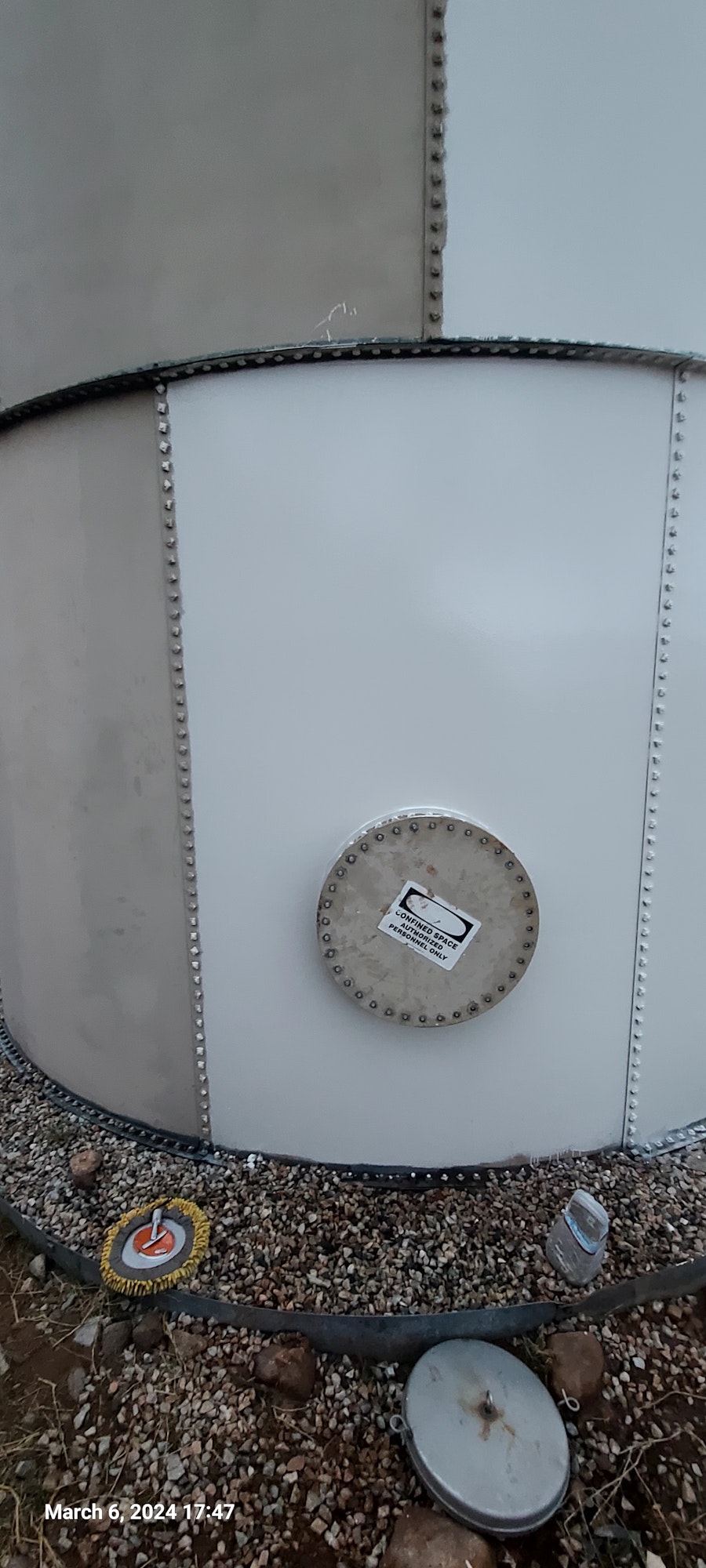

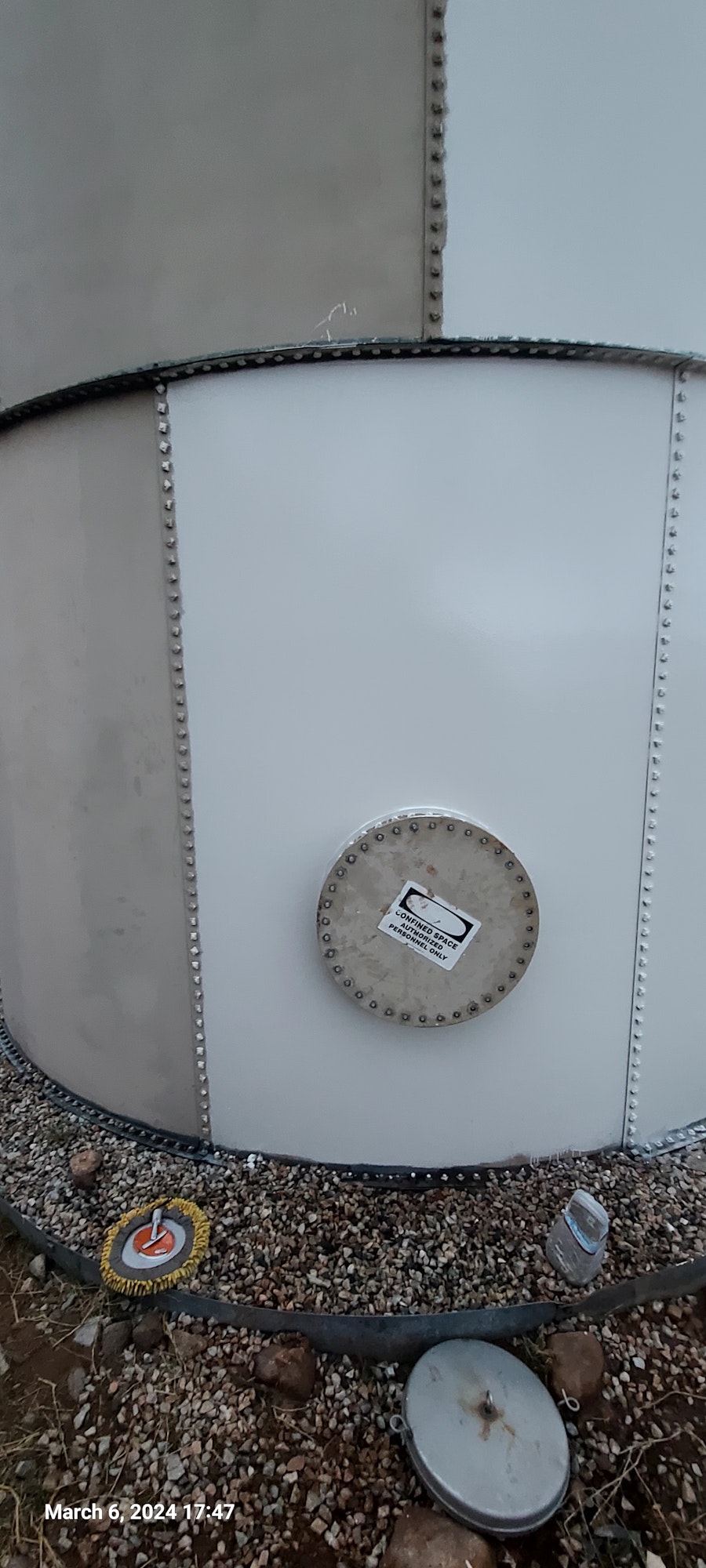

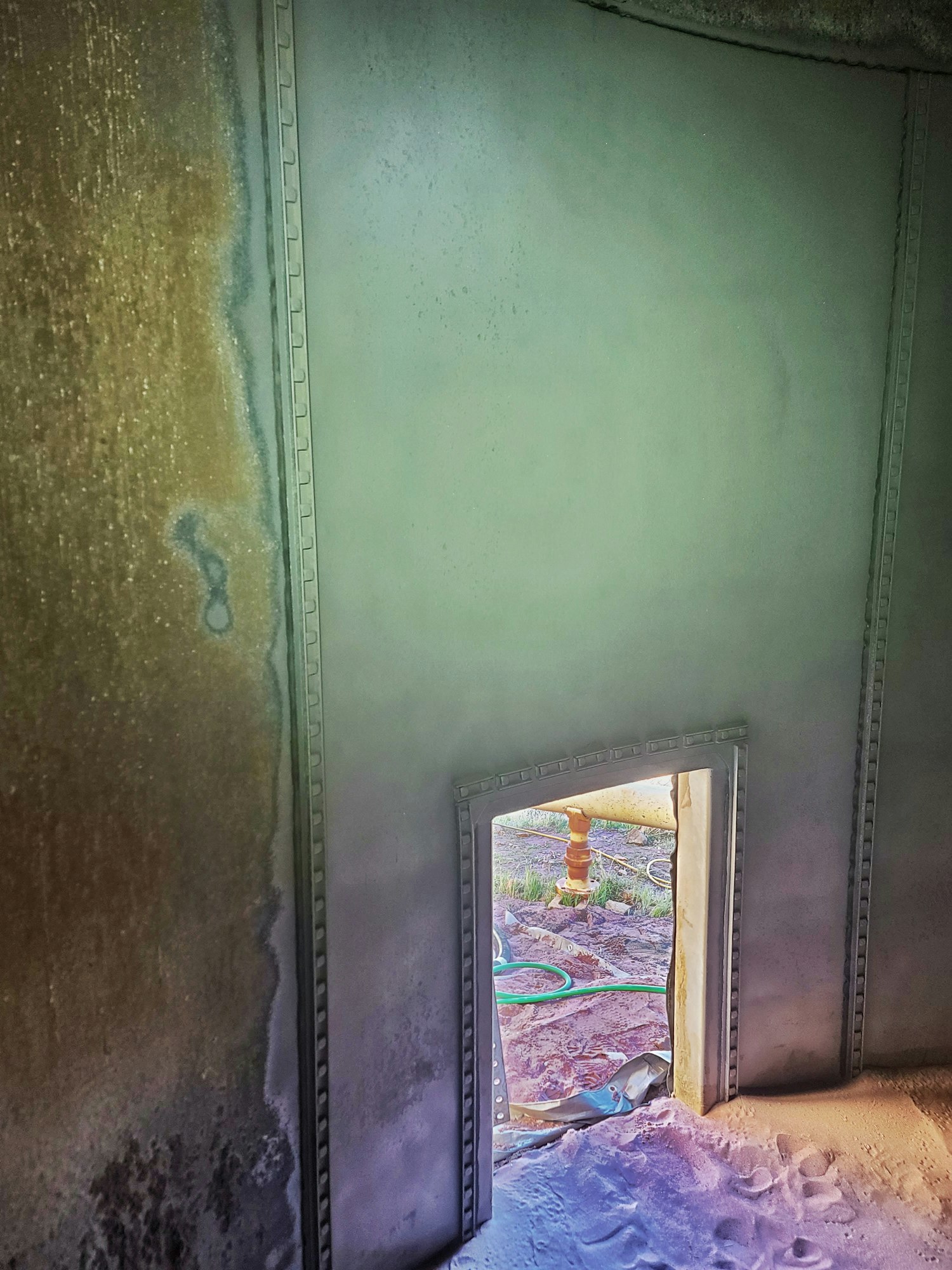

Inspections and Cleaning

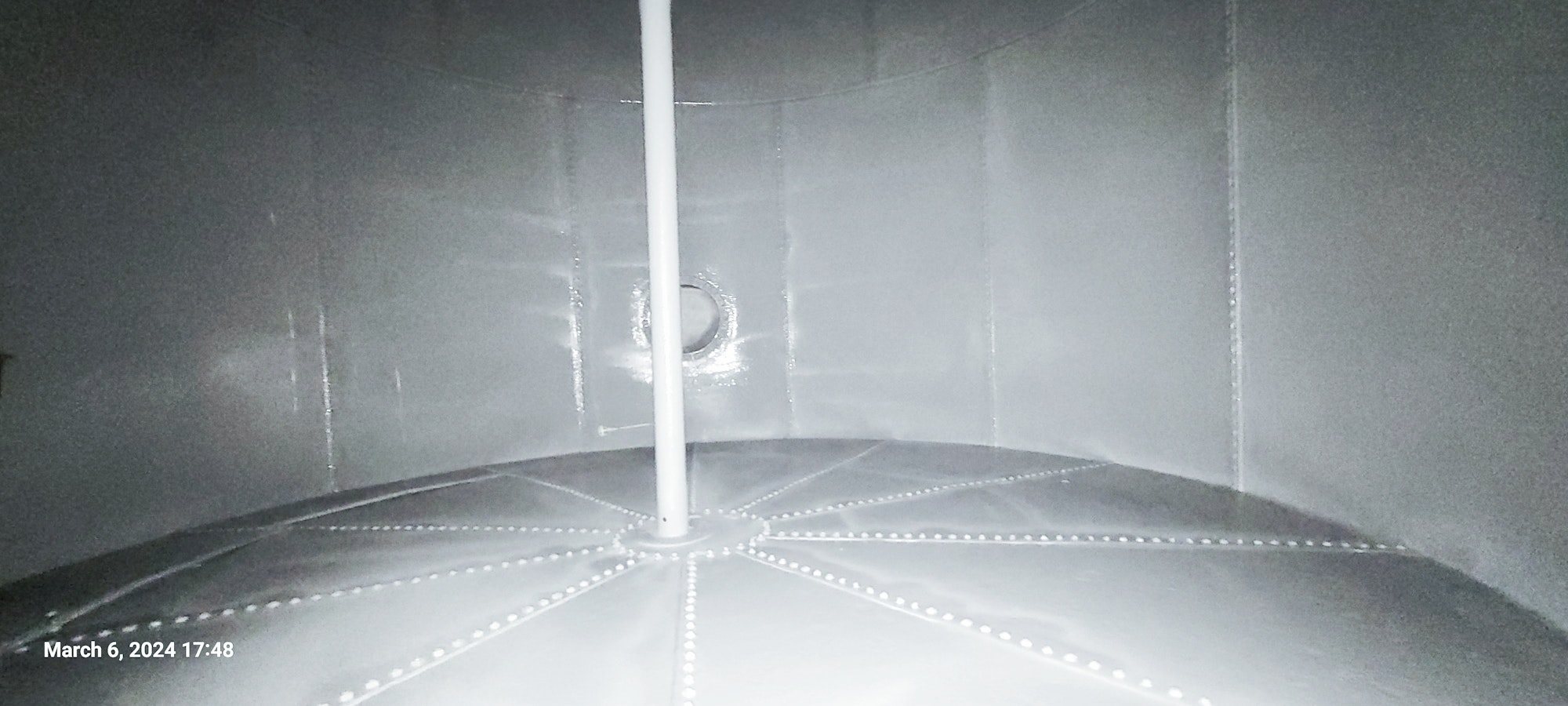

AVHCWD has all of our water storage tanks inspected and cleaned every 3-5 years, or sooner if necessary. Our last inspection and cleaning was performed in January 2023. In May 2023 the east Mesa Vista Tank sprung a leak on the bottom and in June was repaired. Due to the age and condition of the Mesa Vista Tanks our Board of Directors approved to have all three (3) storage tanks re-lined. Marine Industrial Tank Diving and Coating (MIT) was awarded the project and on March 1, 2024, work began.

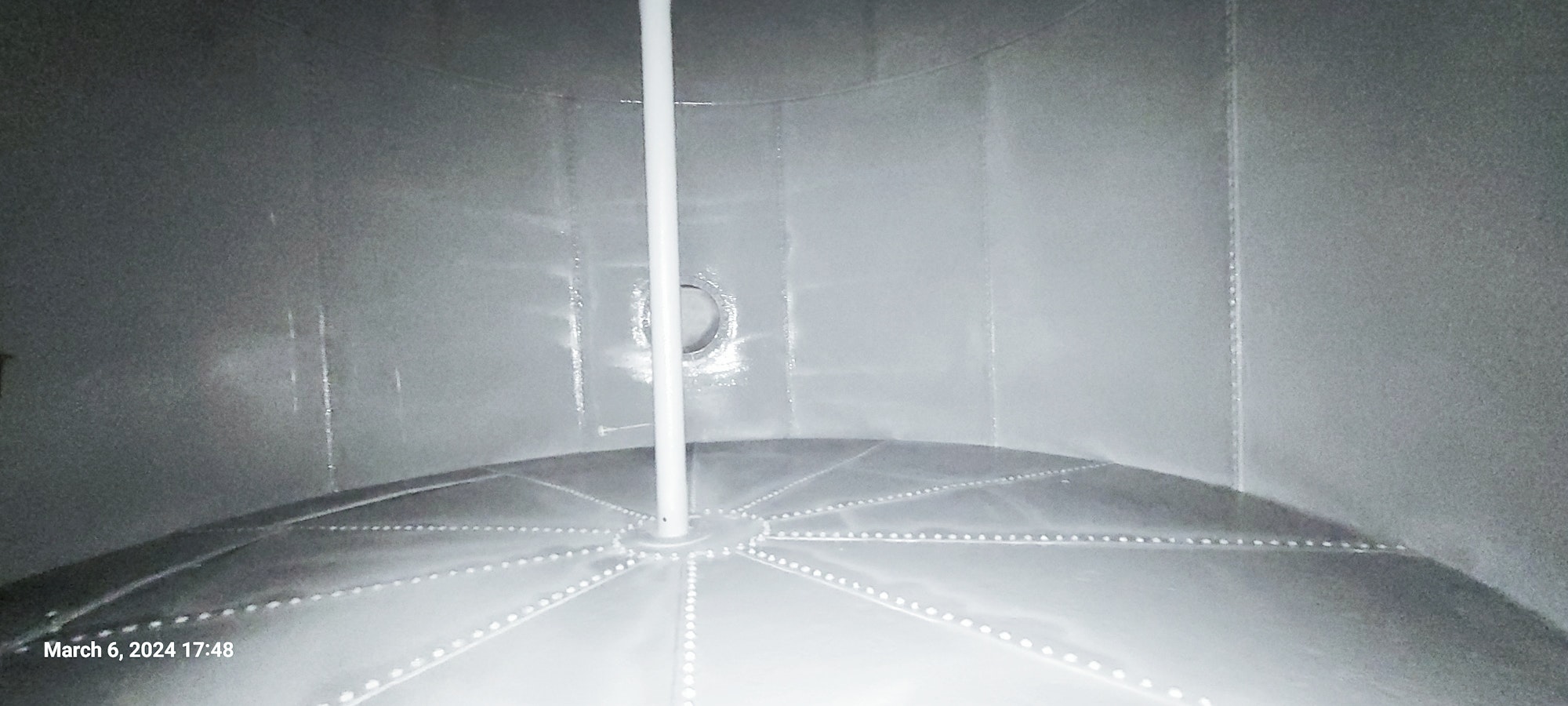

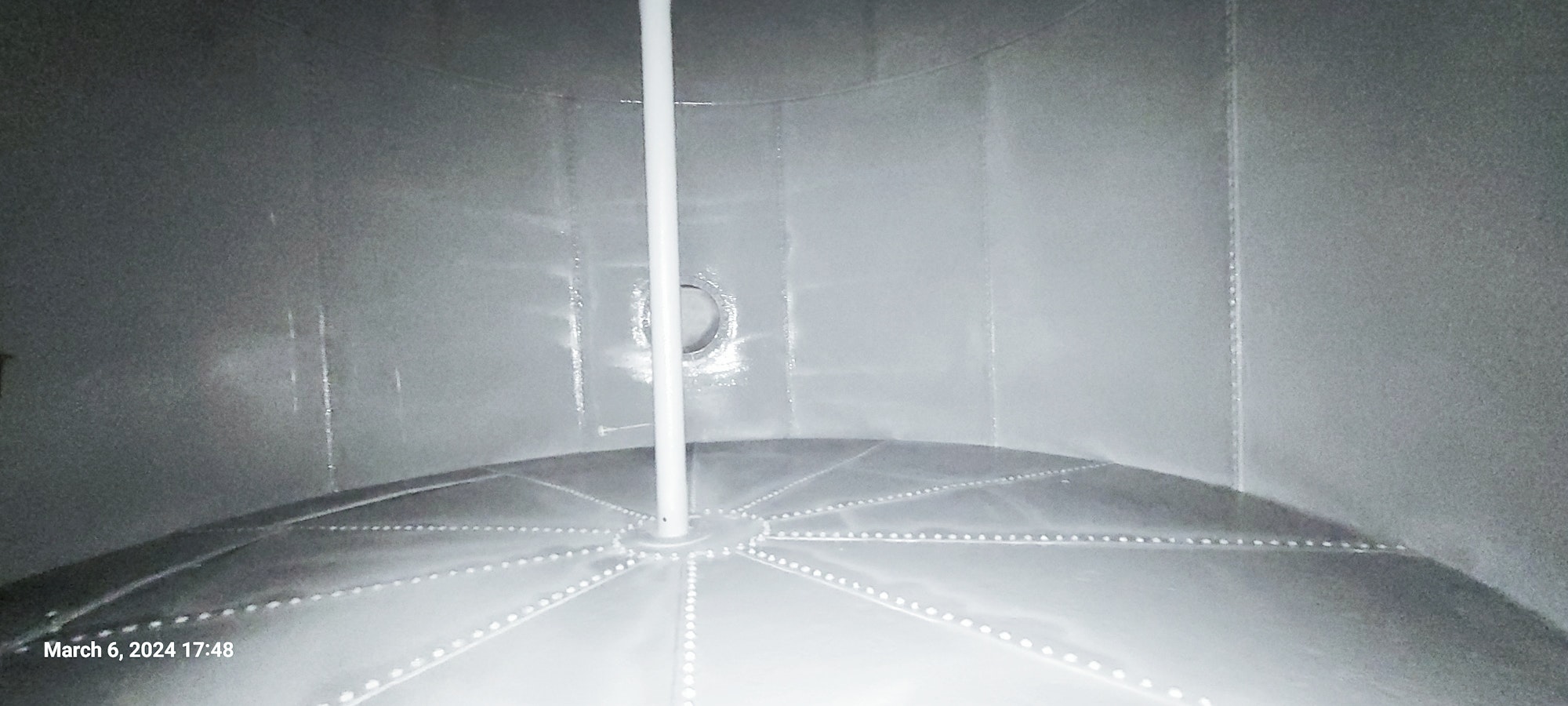

MIT will provide equipment, materials, labor, and insurance. This will be for the complete interior preparations

and relining of three 20kg Steel Bolted tanks.

- Safety - Confined Space, Constant Atmospheric Air/Gas Monitoring, Fall protection, and OSHA 30 trained work crew, NACE Level 2

- Provide entry permit, testing, and gas monitoring of the atmosphere in the tank as required for the safety of crew on the interior at all times.

- Provide a scaffold to access the complete interior of the tank.

- Provide all needed oil-free, Air compressors- Verify oil-free air- by way of “Blotter Test”.

- Blasters to wear proper PPE- Ear Plugs, Fresh Air-supplied Blast Helmets, Coveralls, Chaps, Fall protection (Harness, Lanyard, and Lifeline), and leather blast gloves.

- Provide Abrasive-blast, using Kleen-Blast 16/30 grit or Garnet to achieve, a 3-4 mil profile near white blast as required by the coating manufacturer. SSPC SP-10.

- Verify results of anchor pattern/profile, by use of Testex Press-O-Film Replica Tape and a Surface profile comparator. (X-course).

Polycoat Product

Polyeuro® 5502-NSF is ANSI/NSF 61 compliance by an ANSI-accredited lab, approved for direct contact with potable water. It is a fast setting, rapid curing, 100% solids, flexible, aromatic, two-component spray polyurea that can be applied to suitably prepared concrete and metal surfaces. Its extremely fast gel time makes it suitable for applications down to -20°F. It may be applied in single or multiple applications without appreciable

sagging and is relatively sensitive to moisture and temperature allowing application in most temperatures. Polyeuro® 5502-NSF offers a tack-free time of less than forty-five seconds and exhibits 450% elongation upon

curing with 50 Shore D hardness.

FEATURES

❖ANSI/NSF 61 Approved for Potable Water

❖Zero VOC (100% Solids) ❖Seamless

❖Excellent Thermal Stability ❖Odorless

❖Low Temperature Flexibility ❖Meets USDA Criteria

❖Good Chemical Resistance ❖No Toxic Vapors

❖Coat Pipe 9” In Diameter or Greater

❖Suitable for 5 Gallon Tanks and Larger

❖Coats Carbon or Mild Steel Metals without Primer

❖Installed With or Without Reinforcement in Transitional Areas

TYPICAL USES

❖Potable Water Tanks - Concrete or Metal

❖Potable Water Pipes

COLORS

Clear/Neutral. Custom colors are available upon request.

Color Packs, when used, must be added to Part B.

PACKAGING

10-gallon kit: 5 gallons Part-A (Isocyanate side) and 5 gallons

Part-B (Resin side).

100-gallon kit: 50 gallons Part-A (Isocyanate side) and 50

gallons Part-B (Resin side).

COVERAGE

Polyeuro® 5502-NSF may be applied at any rate to achieve

the desired thickness. Theoretical coverage for 1 mil thickness is

one gallon per 1600 sq. ft.

SURFACE PREPARATION

In general, coating performance and adhesion are directly proportional to surface preparation. Most failures in the performance of surface coatings can be attributed to poor surface preparation. Polyurea coatings rely on the structural strength of the substrate to which they are applied. All surfaces must be free of dust, dirt, oil, grease, rust, corrosion, and other contaminants. When coating substrates previously used, it is important to consider the possibility of substrate absorption, which may affect the adhesion of the coating system, regardless of the surface preparation. Polycoat recognizes the potential for unique substrates from one project to another. The following information is for general reference and project-specific questions, contact Polycoat.

The scope of work includes removing the sediment from the interior ceiling, walls, and floor. Resurfacing and

relining tank interior floors and walls and ceiling. All workmanship and materials will meet or exceed the American Water Works Association. D-102-10 standards for tank coatings. All workmanship will be guaranteed for two years from the date of completion.

WATER QUALITY

Apple Valley Heights Water District routinely monitors for contaminants in your drinking water. Drinking water, including bottled water, may reasonably be expected to contain at least small amounts of some contaminants. The presence of contaminants does not necessarily indicate that the water poses a health risk. More information about contaminants and potential health effects can be obtained by calling the EPA's Safe Drinking Water Hotline at (800) 426-4791 or on the EPA's website:(www.epa.gov/safewater).

For additional water quality or operational clarification, please see our annual Consumer Confidence Report or contact the District Office at (760) 247-7330. We want our valued customers to be informed about their water utility. If you want to learn more, you are invited to attend any regularly scheduled Board of Directors meetings held every third Wednesday of the month. The meetings are held with open-session discussions at 6:00 p.m. All meetings will be held at the District office located at 9429 Cerra Vista Street, Apple Valley, CA 92308.

The project is expected to be completed by the end of March 2024